Heidolph Hei-VAP Expert Control Motorlift-Model with G3 CL glassware

Article Number574-02305-00

Unit of MeasurePiece

Lift motor lift

Rotation speed range 10 - 280 rpm

Rotation speed indicator 5" LCD color graphic display

Heating capacity 1,300 W

Overheat protection bath cut-off at 5 °C over set temperature via separate PT 1000

Bath temperature setting 5" LCD color graphic display

Heating bath temperature control electronic / digital

Max. size evaporating flask 5 l

Integrated vacuum controller Yes

Timer Yes

Integrated Hei-CHILL controller Yes

Vacuum program DAA mode

requires AUTOaccurate-Sensor Yes

Programmable ramps Yes

Condensing surface 2.200 cm²

Hei-VAP Expert Control

Adds numerous smart features to the Hei-VAP Expert, as well as an overview of all parameters and the current process

5" touch display for controlling the entire system including the vacuum and the cooling temperature

For precise monitoring, the pictogram on the display also symbolizes active functions

Separate knobs for quick access: the right one for direct vacuum control, the left one for the rotation

Setting of values either via the touch display or the separate quick access knobs

Direct access to two favorites on the start screen

Expandable solvent library. You can also transfer your own favorites to other devices using a USB stick

Define and save own evaporation processes (ramps)

Automatically evaporate with the Dynamic AUTOaccurate Program (DAA). Convenient and customizable: from foam avoidance to highly efficient evaporation

With USB and Micro SD interface for easy installation of software updates and transfer of individual favorites from one device to another

The Hei-VAP Control principle

Hei-VAP Expert Control and Ultimate Control allow to centrally control all process parameters: vacuum, cooling temperature, rotation and heating bath temperature.

Evaporate with a tap:

Customizable solvent library

Automatically find boiling points with Dynamic AUTOaccurate

Simply save processes as favorites

Automatic evaporation with Dynamic AUTOaccurate (DAA)

The DAA allows you to start a fully automated distillation process already during the heat-up phase of the heating bath.

The system vacuum is dynamically adjusted to the changing heating bath temperatures until the heating bath has reached its defined temperature.

The boiling points of one or more fractions are identified through the steam temperature gradation of the mixture during continuous automatic pressure control

You can freely set whether one or more fractions are to be distilled. The vacuum control is fully automated for each fraction

You can control the evaporation speed by adjusting the ratio of steam temperature to cooling temperature

Samples are distilled precisely

Automation with sensors ensures noticeably higher precision

To protect your sample, motor lift models automatically remove the evaporating flask from the heating bath at the end of the process

All Hei-VAP rotary evaporators have a safety heating bath with overheating and dry running protection, ergonomic handles, double wall and an integrated spout

Universal heating bath for all flask sizes up to 5 l (no retooling required). The sturdy metal connection to the device’s base allows variable distances for the heating bath up to 200 mm without tilting

Digital displays allow continuous monitoring of the current values and, thanks to protection class IP 42, protect the electronics reliably against dripping water and dust

Separate knobs with intuitive LED ring light system not only allow visual process control, but also direct intervention in the evaporation process at any time

The locking function of the knobs prevents unintentional adjustment of the values

Residual heat indicator: When the function is deactivated and in standby mode, flashing and the display of the residual heat warn of the risk of burns (> 50 °C)

The standby button stops all functions and, when using a motor lift model, lifts the evaporating flask from the heating bath

In order to prevent short circuits and corrosion systematically, the cable connections of the operating panel and the heating bath comply with the high protection class IP 67

Additional safety from a single source: From the transparent plastic coating of the glassware to guard shield and guard hood (implosion protection) to IQ-OQ documentation and certification

All models are available with hand or motor lift

The patented flask clamp Easy-Clip facilitates attaching and changing of the evaporating flask. The mechanism gently separates ground glass joints to prevent glass breakage

The versatile operating concept meets all requirements with digital display or touch display

Intuitive operation, as all settings are configured centrally on the operating panel. In combination with the Control-Box, the panel can even be used as the central control unit to regulate the vacuum and the Hei-CHILL recirculation chiller as well

The detachable panel with optional extension cable and holding device allow quick and easy operation even outside closed fume hoods

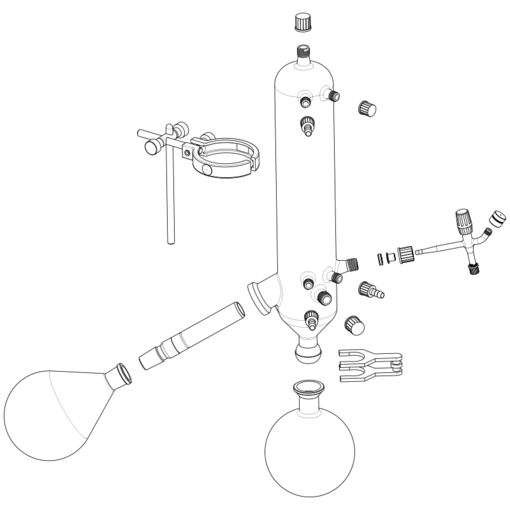

Easy ventilation thanks to the ground-free condenser design: The ventilation cap with PTFE inlay and threaded connection avoids stuck glass – without grease. Optionally, a venting valve with refill function is also available

FDA-compliant materials for all active and passive media-contacting components permit a broader range of application and research at the highest level

Convenient release for individual adjustment of the angle of inclination from 20° to 80° and height stop to limit the immersion depth up to 160 mm

The optionally available automatic module Distimatic permits fully automatic distillation in unattended continuous operation

No unnecessary additional costs: The patented clamping sleeve effectively prevents the vapor tube from getting stuck in the drive

With the patented Easy-Clip’s integrated screw thread, stuck evaporating flasks can be released safely and easily

Ground-free condenser design with grease-free threaded connections

The highly resistant and particularly durable PTFE vacuum seals achieve maximum tightness and reduce expenses for spare parts in the long run

The unique tightness of the vacuum system leads to shorter process times, reduced energy costs and purest results

The universal heating bath is suitable for all flasks up to 5 l, without additional costs for retrofitting

Even greater efficiency with up to 40 % higher evaporation rates: The intelligent design of the XL condenser provides 57 % more cooling surface at almost the same height as previous standard vertical condensers

Quality that pays off. Corrosion-free die-cast housings with condensation-repellent varnish and maintenance-free motors guarantee unrestricted continuous operation and a long lifespan with significantly lower maintenance costs

Media-contacting plastic parts such as the screw connection for mounting the condenser and the clamping sleeve on the vapor tube are made of highly resistant PPS to ensure a long lifespan

Many of the current series’ spare and wear parts are forward and backward compatible with earlier models