UV-C for better yields

Pest control in the hemp industry

In this California growing facility, ultraviolet germicidal UV-C irradiation is used in conjunction with anenvironmental control system to prevent mold and mildew spores that form in the flowering space and ruin the crop.

!!! up to 60% more yield !!!

CULTIVATE - AIR QUALITY

In the legal cannabis sector, undesirable microbes canin the air stream can cause large investments to go up in smoke.

CANNABIS CULTIVATION FACILITIES:

THE ROLE OF UV-C IN PROTECTING CROPS & EFFICIENCY

Not only can such microbes ruin the crop, but they can also cause the entire plant to close due to health violations.

THREATS TO CANNABIS GROWTH

There are a variety of naturally occurring microorganisms in the air that can cause plants to develop mold or mildew, rendering them worthless. Standard HVAC systems can actually increase this risk, as these damp and dark systems provide a perfect breeding ground for microbial growth.

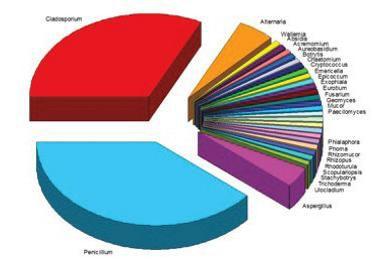

Worse, ventilation systems are very efficient at spreading microscopic spores throughout a building. The figure to the right shows a breakdown of the most common molds in indoor air.

Air filtration systems can keep the indoor growing area free of Fungal spores in the air. Botrytis cinerea spores (commonly known as gray mold) are about 11-12 microns in diameter (Gull 1971), and spores of this size are retained by filters with a MERV of 12 and higher. Even a dust filter of the lowest (MERV 6-8) can remove 50% of the spores from the air, and multiple passes (with recirculated air) can remove the spores completely (Kowalski 2006 & 2009).

While air filtration provides protection from airborne spores, it has a drawback for agricultural production. The humidity in the air, which is necessary for cannabis plants to thrive, can cause the filter material to become damp, which encourages the proliferation of trapped microbes. Botrytis cinerea spores originate in the wild and are brought indoors through shoes and clothing. They are also found as common contaminants in about half of the indoor environments in the United States, with mean concentrations of about 45-49 CFU/m3 (Shelton 2002).

Therefore, it is important that workers cleanse and decontaminate themselves before entering a sterile cultivation environment. Normal disinfection procedures, such as those used in hospitals, can be adapted for growing rooms. Other methods of controlling Botrytis cinerea include traditional fungicides. But some of these methods can leave dangerous residues that are not suitable for consumption by critically ill patients (Cervantes 2006). Organic methods are also being investigated, including the use of competing or parasitic microorganisms (Wu 2013, Schumacher 2011, Costa 2013).

Air quality in the growing rooms can also be controlled by air filtration and positive pressure, while disinfection of the interiors can be performed with chemicals such as bleach.

UV-C IN CULTIVATION FACILITIES

There are two approaches to using UV-C to control mold and proliferation of bacteria in indoor cannabis gardens:

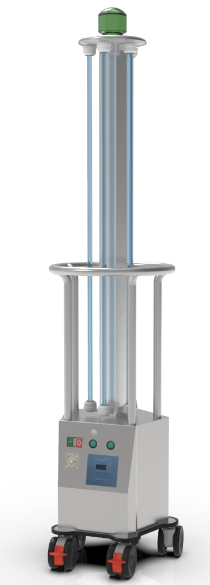

1) UV-C air flow disinfection systems

2) UV-C surface disinfection systems

AIRFLOW DISINFECTION

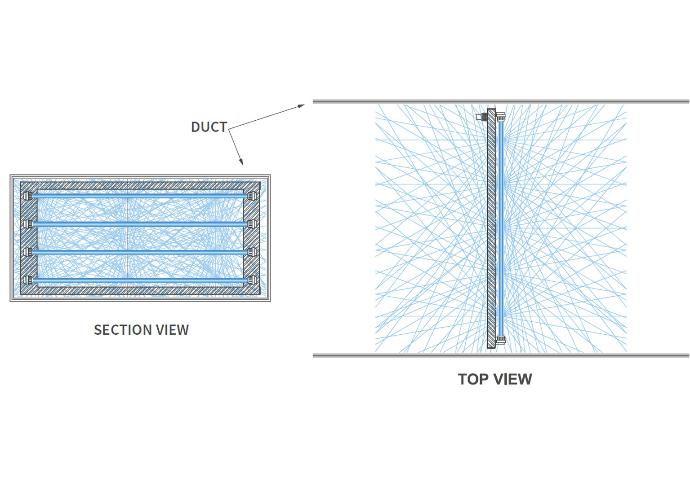

Airflow disinfection systems use UV-C lamps to control pathogens from outdoor and/or exhaust air (which contain airborne pathogens).

Kill rates in excess of 99.9% on the first pass have been modeled and since the air is recirculated, concentrations are further reduced with each subsequent pass ("multiple dosing").

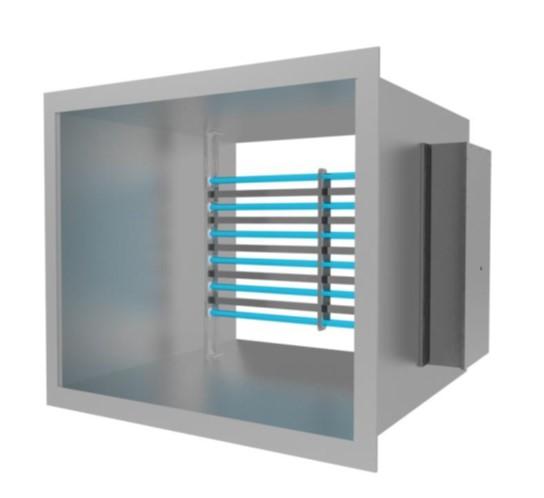

HVAC-SURFACE CLEANING

UV-C prevents these areas from becoming microbial reservoirs for pathogen growth that eventually spreads into the air streams. They can also provide an airborne pathogen kill of up to 30% with added cleanliness, heat exchange efficiency, and energy consumption (ASHRAE 2011- Fencl 2013/2014).

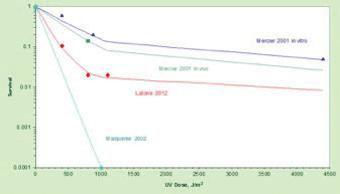

Latorre et al. (2012) testeten die Wirksamkeit von UV-A, UV-B, und UV-C-Bestrahlung auf Botrytis cinerea und stellten fest, dass UV-C das wirksamste Spektrum ist. In der Studie wurde ein Philips-Modell F15T8BLB mit einer UV-Leistung von 20 W.

The results showed no survival of conidia (spores) at the highest UV dose of 1,100 J/m2. Mercier et al. (2001) used UV-C irradiation in the range of 400- 4,500 J/m2 with a General Electric G30T8 UV lamp (30 W UV power) to control rot on peppers caused by Botrytis cinerea. Spore germination was inhibited both in vivo and in vitro, with spore survival rates of 0-5% after a total UV dose of 4,400 J/m2. Marquenie (2002) irradiated Botrytis cinerea spores with five fluorescent UV lamps at 8 W UV power each, and the results show the results show a one-step curve up to the maximum tested dose of 1,000 J/m2.

The range of D90 values, i.e., the dose of "disinfection" of the spores required for 90% disinfection of the spores, is about 440-2,000 J/m2. This range of UV sensitivity compares well with other fungal spores such as Aspergillus or Penicillium (Kowalski 2009).

A critical aspect of designing indoor facilities for medical marijuana cultivation is the control of airborne fungal spores, and although most existing facilities are poorly suited to prevent fungal spore intrusion, they can usually be retrofitted with air filters, fentilators, and UV systems to make them relatively free of spores. However, it is important that the facility is airtight and pressurized to maintain the high level of cleanliness necessary to prevent mold outbreaks. And ideally, each cultivation center should have a pressurized anteroom that will not allow spores to enter from the outdoors or to reach the outdoors. Operating protocols and regular decontamination are necessary to maintain a high level of cleanliness and disinfection.

CASE EXAMPLE:

SOLUTIONS FOR ACCELERATED GROWTH

A standard feature built into all AG systems is germicidal UV-C irradiation from UV Resources of Santa Clarita, Calif. The 253.7 nm C-band wavelength inactivates virtually all microorganisms that form on HVACR cooling coils. Left unchecked, these microbes can cause mold and mildew and ruin entire crops.

"Placing UV-C lamps directly above the cooling coils is critical for maintaining a healthy, successful plant," Guckian explains.

To improve yields, the plant installed a dozen 35-ton AG air conditioners, each supplying a 70-lamp production room. "The installation is very simple," Guckian explains. "The units aremounted on the floor outside the light room. A small hole is cut in the wall for return air, and supply air is routed into a duct system."

After seven months of operation, the plant has increased its yield by about 60% - from two pounds per lamp to about 3.25 pounds per lamp.

"It's relatively inexpensive protection for an incredibly expensive crop," Guckian says. "You shouldn't even build a plant without it. This is not even a question."

Our consulting team

Personal consultation is important to us!

We will be happy to advise you on site. During a tour, a decision can be made easily and quickly,

what options are available to keep your production germ-free.

Eveline Heiniger (Aussendienst)

Eveline Heiniger is your contact person for on-site consulting. You can reach Ms. Heiniger by e-mail [email protected] oder per Telefon +41 79 711 73 73

Zuständig für: ZH/GR/LU/SZ/SH/TG usw.

Andrea Seiler (Aussendienst)

Andrea Seiler is the right contact person for on-site consulting. You can reach Ms. Seiler by e-mail [email protected] oder per Telefon +41 79 848 73 73

Zuständig für: AG/BE/BS/BL/SO/FR usw.

Dr. Felix Joho

Felix Joho is here for you in our office.

You can reach Mr. Joho by e-mail [email protected] oder per Telefon

+41 52 345 02 02

Claude Haltiner

Claude Haltiner is the managing director and owner of PMI Labortechnik GmbH. With his many years of experience in the laboratory trade, he supports the field service team.

Literature

The content of this page is taken from Engineering Systems, June 2018 issue.

Referenzen / Quellen

Borchardt, D. (2017, March 01). "Marijuana Industry Projected To Create More Jobs Than Manufacturing By 2020." Retrieved . September 28, 2017

Boyd-Wilson, K., Perry, J., und Walter, M. (1998). "Persistenz und Überleben von saprophytischen Pilzen antagonistisch zu Botrytis cinerea auf kiwifruit leaves." Proc of the 51st Conf of the New Zealand Plant Prot Soc, Inc. 96-101.

Cervantes, G. (2006). Marihuana-Gartenbau: The Indoor/Outdoor Medical Grower's Guide. Van Patten Publishing.

Cleanlightdirect (2016). "Töten Sie Mehltau und Knospenfäule mit UV light." Costa, L., Rangel, D. E. N.,

Morandi, M. A. B., and Bettiol, W. (2013). "Auswirkungen von UV-B-Strahlung auf die antagonistische Fähigkeit

of Clonostachys rosea to Botrytis cinerea on strawberry leaves." Biological Control 65, 95-100.

Gull, K., und Trinci, A. P. J. (1971). "Feinstruktur der Sporenkeimung in Botrytis cinerea." J Gen Microbiol 68, 207-220.

Heuvelink, E. (2006). "Reduzierung von Botrytis in Gewächshauskulturen: periodische UV-Licht-Behandlung bei Tomatenpflanzen". Universität Wageningen, Horticultural Production Chains, Wageningen, Niederlande.

Kowalski, W. J., Bahnf leth, W. P., Witham, D. L., Severin, B. F., und Whittam, T. S. (2000). "Mathematische Modellierung von UV-C für die Luftdesinfektion". Quantitative Mikrobiologie 2(3), 249-270.

Kowalski, W. J. (2006). Aerobiological Engineering Handbook: A Guide to Airborne Disease Control Technologies. McGraw-Hill, New York.

Kowalski, W. J. (2009). Handbuch zur ultravioletten keimtötenden Bestrahlung: UVGI für Luft- und Oberflächen-desinfektion. Springer, New York.